A fleet of more than two dozen Euro 6 compliant MAN trucks purchased by Sasol will be operational soon on South Africa’s roads – fuelled exclusively by the company’s low-sulphur diesel.

Making the announcement last week at the TruckX Conference and Expo held at Kyalami, Adrian Velaers, Sasol’s Senior Technical Advisor, said the company was confident that the purple-coloured fuel – sold at the pumps as Turbodiesel ULS – was more than clean enough to power the fleet’s Euro 6 compliant engines without causing technical problems.

“We guarantee that Turbodiesel ULS’s sulphur content – which is advertised at 10ppm or less – is so low that it can be used to power Euro 6 compliant engines without causing any damage,” he said.

“In combination with Ad Blue – an aqueous urea additive that is injected into the exhaust system – we believe the fuel will make it possible to cut tailpipe emissions to the point where only harmless gases are released into the atmosphere.

“The company’s concern for a cleaner environment and increased efficiency has driven the decision. We are so confident of the quality of our fuel that we believe that the gases emitted from the exhaust pipes of our trucks will be cleaner than the air that’s sucked into the engines for combustion purposes,” he said.

According to Velaers, Turbodiesel ULS – a synthetically produced fuel – contains advanced detergent and lubricity additives that help to keep engines and fuel injection systems clean and well protected.

“The fuel allows latest technology vehicles fitted with exhaust after treatment devices to operate freely. The development is a step forward in moving South Africa closer to cleaner fuel specifications in line with international standards,” he maintained.

Velaers added that the clean-up effect of performance additives contained in the fuel helped to improve economy even in older generation engines. “We’ve conducted tests which show how, over a period of time, the removal of deposit build-up allows engines to operate at optimum efficiency and sustain optimum fuel consumption,” he said.

Christopher Kabosha, Senior Manager for Corporate Affairs and Marketing at Sasol Energy, said the company was excited about putting its new tanker fleet into operation. “It will bring significant advantages to our business and our customers,” he said.

“We’re proud to be at the cutting edge of industry-leading technology. Our premium diesel offers significant advantages to our customers through enhanced fleet efficiency and environmental sustainability responsibility. It’s a significant milestone.”

According to Kabosha, Sasol was the first company locally to operate a fleet of MAN Euro 6-compliant trucks. “It will be one of the most efficient commercial truck fleets in South Africa,” he promised.

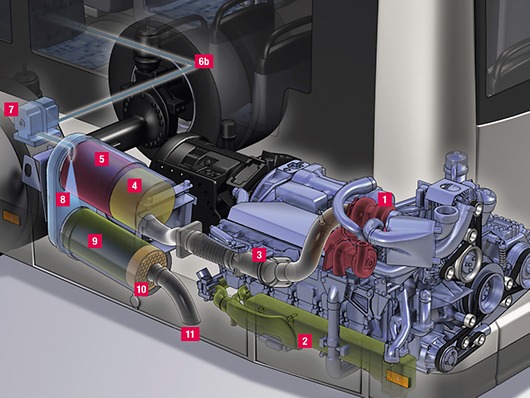

Technical Components, MAN Euro 6 Compliant Engine

- Exhaust Gas Turbocharger: The two-stage turbocharger increases the engine’s efficiency, thereby ensuring lower fuel consumption and clean low-particulate combustion.

- Exhaust Gas Recirculation: Decreases the temperature at which fuel combusts in the cylinders, resulting in lower nitrogen oxide emissions.

- Exhaust Manifold: Exhaust gas from the engine passes through the heat-insulated exhaust pipe into the exhaust muffler for after-treatment.

- Diesel Oxidising Catalytic Converter: By means of a platinum coating, the oxidising catalytic converter transforms the polluting carbon monoxide and hydrocarbons into nontoxic CO2 and water.

- Particle Filter: The particle filter captures up to 99% of all soot particles from the exhaust gas flow. A chemical process enables the filter to continually re-clean itself.

6a. AdBlue Tank: The aqueous urea solution is stored in the AdBlue tank and is used as a reduction agent for the exhaust gas after-treatment in the SCR catalytic converter.

6b. AdBlue Line: The urea solution passes through a heated line from the AdBlue tank to the AdBlue mixer.

- AdBlue Dosing Module: The electronic dosing module uses sensors to determine the quantity of AdBlue required for nitrogen oxide reduction and injects it into the AdBlue mixer.

- AdBlue Mixer: In a hydrolysis section in the AdBlue mixer, the injected urea solution turns into ammonia, which is required for the reaction in the subsequent SCR catalytic converter.

- SCR Catalytic Converter: By the princliple of selective catalytic reduction, the SCR catalytic converter turns most of the nitrogen oxide into harmless nitrogen and oxygen.

Ammonia-Blocking Catalytic Converter: The blocking catlytic converter prevents excess ammonia from being emitted.

- Exhaust Tailpipe (Or Outlet): The purified exhaust is discharged from the tailpipe. Sensors continuously monitor the nitrogen oxide values.